Driving Precision in Automation: WIKA’s Strategic Evolution in Industrial Measurement

The shift to digital automation requires highly accurate and connected measurement solutions that enable real-time monitoring and predictive analytics. Precision instrumentation plays a crucial role in optimising operations and ensuring regulatory compliance within complex industrial environments. Meeting these evolving demands involves transitioning from traditional mechanical devices to advanced IIoT-enabled sensors. In response, WIKA has developed modular sensors designed for seamless integration and scalable performance. These solutions support the growing need for reliable, intelligent measurement, reflecting the company’s adaptation to the challenges of modern industrial automation.

Innovations Enhancing Automation Precision

Recent product developments from WIKA demonstrate their emphasis on intelligent sensing combined with robust connectivity. The NETRIS® line, for instance, comprises radio units designed to communicate via LoRaWAN® and LPWAN networks. These enable remote, secure data transmission from various sensing instruments to cloud environments or centralised control systems. This design is critical for operations requiring secure communication across expansive or remote installations.

Temperature monitoring has also been enhanced through compact resistance thermometers such as the TRU and TRW models, which are optimised for wireless functionality in confined or inaccessible environments. Similarly, the TGU73.100 gas-actuated thermometer can interface with radio units to facilitate thermal data collection in industrial settings.

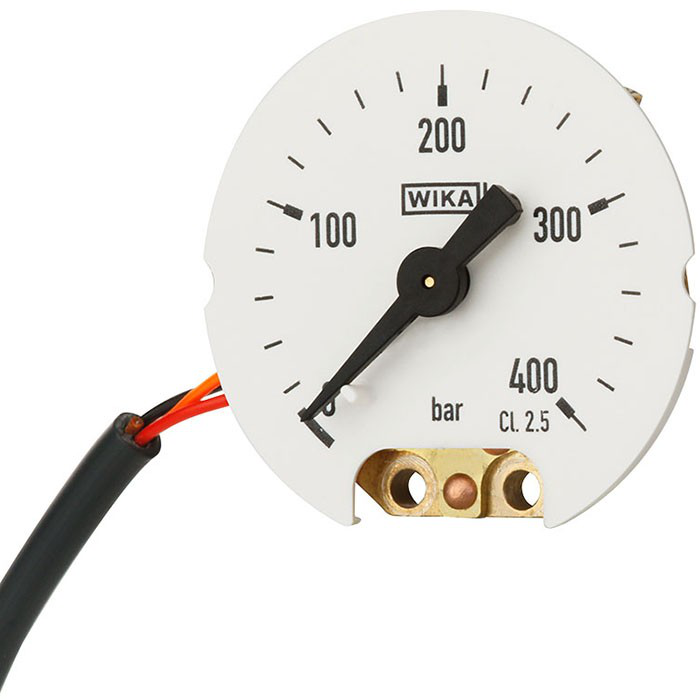

For pressure measurement, the PGU and PGW series accommodate both wired and wireless communication. These instruments ensure precise readings and maintain operational stability under adverse conditions. Collectively, such innovations illustrate WIKA’s focus on merging accurate sensing with intelligent transmission to serve automation-driven sectors effectively.

Embracing IIoT and Digital Transformation

The Industrial Internet of Things (IIoT) is reshaping how industries manage assets by prioritising data visibility, predictive insights, and operational resilience. A key aspect of this transformation is the real-time monitoring of critical parameters across distributed systems. Responding to these demands, WIKA through its WEgrid Solutions division has developed digital platforms for gas-insulated switchgear that monitor pressure, temperature, humidity, and SF₆ gas density for centralised diagnostics and smarter maintenance planning.

WIKA’s intelligent, modular sensors integrate directly into industrial networks, enabling real-time data flow from field devices to cloud or control platforms. These systems apply advanced algorithms to detect anomalies, support predictive maintenance, and adjust operations as needed. This functionality not only minimises downtime and asset failures but also ensures consistent performance. In an automation-driven landscape, WIKA’s IIoT solutions align with industry demands for reliability, efficiency, and compliance.

Ensuring Safety and Compliance in High-Risk Sectors

In sectors where the margin for error is minimal, WIKA maintains a firm focus on safety and regulatory adherence. Its instrumentation is developed in accordance with international certifications such as ATEX, IECEx, SIL, FDA, and GMP. This adherence ensures not only operational safety but also legal and environmental compliance in highly regulated industries like oil and gas, pharmaceuticals, and energy.

In power distribution, for instance, WIKA’s gas density monitoring equipment supports early leak detection and identifies by-products of SF₆ gas decomposition, essential for protecting both equipment and the environment. The devices used in such settings incorporate fail-safe diagnostics and adhere to secure communication protocols, mitigating the risks associated with hazardous environments.

In pharmaceutical manufacturing, sensors are designed to meet hygienic design principles and enable full traceability, thus satisfying stringent In power distribution, for instance, WIKA’s gas density monitoring equipment supports early leak detection and identifies by-products of SF₆ gas decomposition, essential for protecting validation requirements. The company’s commitment to continuous diagnostics and calibration services ensures that measurement instruments remain reliable throughout their operational lifecycle.

Supporting Customisation and Integration for OEMs

The automation landscape requires highly tailored solutions, especially for original equipment manufacturers (OEMs) and system integrators. Recognising this, WIKA offers a modular approach that supports specific configuration requirements. Instruments can be customised in terms of output signal types, material compatibility, and physical form factors.

WIKA’s portfolio allows for seamless integration with existing and new automation architectures through support for analogue outputs (e.g., 4–20 mA), digital protocols (such as Modbus), and advanced wireless standards like LoRaWAN®. This versatility ensures the smooth incorporation of WIKA’s devices into diverse operational contexts.

Collaboration is also a key part of WIKA’s support model. Through joint development, simulation, and field validation, the company works closely with partners to ensure that the performance and compliance of instruments meet industry-specific standards. This approach allows clients to adapt their systems quickly as needs evolve while maintaining long-term operational efficiency.

Strategic Alignment with Industry 4.0

WIKA’s proactive stance on digitalisation extends to its involvement in shaping global Industry 4.0 frameworks. As a contributor to the Digital Data Chain Consortium (DDCC), the company is helping define interoperable standards for digital information exchange. This includes the adoption of IEC 61406 for unique device identification and VDI 2770 for manufacturer documentation standards.

These measures are critical as manufacturers prepare for the EU’s Digital Product Passport (DPP) requirements. WIKA supports these future mandates through technologies such as the Asset Administration Shell (IEC 63278), which provides a digital twin for lifecycle data sharing. These initiatives ensure traceability, standardisation, and interoperability, which are the core requirements for smart manufacturing ecosystems.

To facilitate seamless system communication, WIKA equips its products with digital interfaces like Modbus and LoRaWAN®, enabling integration into automation systems at every level. This technical foresight positions WIKA not only as a supplier of instruments but as an enabler of intelligent manufacturing infrastructure.

Conclusion

The trajectory of industrial automation is marked by a clear shift toward smarter, more connected systems that prioritise efficiency, reliability, and regulatory alignment. As operational demands become more complex, the role of accurate and adaptable measurement technology becomes increasingly central to system design and performance.

Within this broader context, WIKA exemplifies a focused, strategic response to industry transformation. Through its intelligent instrumentation, modular design philosophy, and active engagement in digital standardisation, the company enables robust integration and data-driven decision-making, key factors in the evolving automation landscape.

WIKA Instruments India Pvt Ltd

Web : www.wika.com