Beyond energy efficiency: Air-Saving Ejectors drive sustainability and reduce global warming in Industry

Industry Segment Manager

Schmalz India Pvt. Ltd.

It’s always a pleasure to share our expertise and work experience with our esteemed customers on innovative vacuum automation solutions. As someone who has spent 18 years across automotive vacuum automation applications, I’ve seen how small innovations can transform entire industries. Today, one such innovation is reshaping Indian manufacturing: Air-Saving vacuum generators.

Walk into any automotive supplier in India today and you’ll hear the same refrain: “Reduce Carbon footprints.” The industry is under relentless pressure to reduce carbon footprints, and every line must deliver zero-defect quality. Yet behind the scenes, many factories still rely on legacy vacuum systems that quietly waste 70% – 90% of compressed air — the second-largest utility cost in manufacturing. This hidden inefficiency drains profits, inflates energy bills, and undermines sustainability goals.

Why Air-Saving Matters

Compressed air is expensive. Every cubic meter wasted is money lost — and emissions added. In fact, energy costs for compressed air have risen nearly 20% in the past three years. From Automotive OEMs to their Tier I and II supplier, that can mean lakhs of rupees in avoidable expenses annually.

Air-saving ejectors directly tackle this challenge. By consuming air only when needed, they cut energy costs by up to 90%. But the benefits go far beyond savings:

- Reliability in harsh Indian conditions – no electronics to fail during voltage dips or monsoon humidity.

- Zero-defect performance – stable vacuum ensures consistent quality, fewer rejects, and lower warranty costs.

- Sustainability impact – each line can reduce CO₂ emissions by over 4 tons annually, equivalent to planting 700 trees.

This isn’t just about machines. It’s about enabling manufacturers to stay competitive, meet government incentives, and align with global carbon neutrality targets.

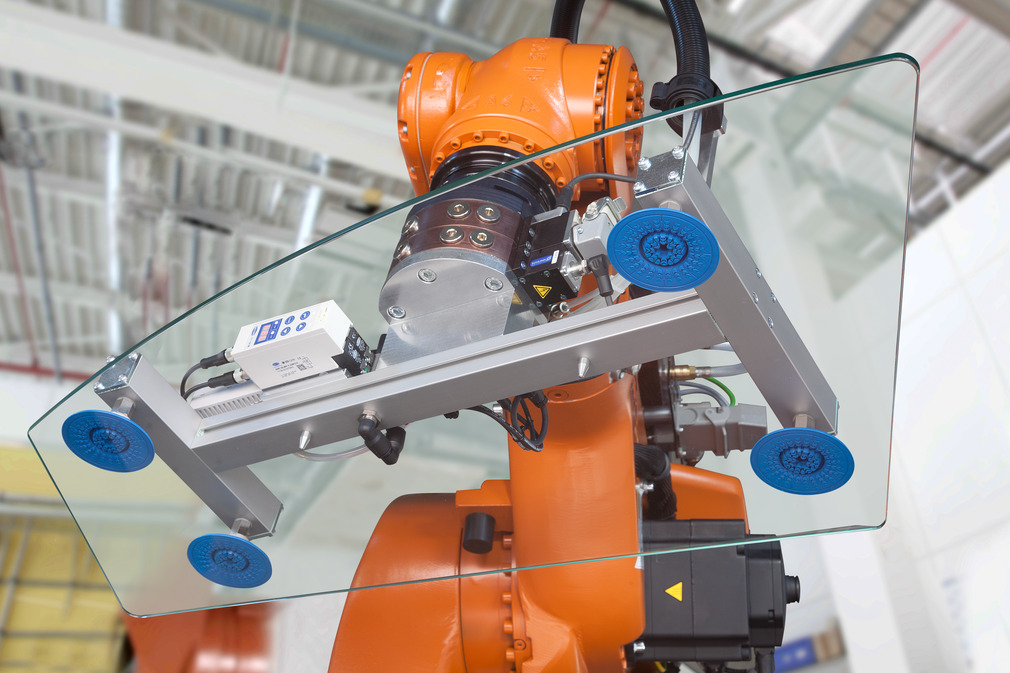

Industrial vacuum automation applications are depending on compressed air supply. Schmalz pneumatically and electrically operated air saving ejectors ensure 90% compressed air savings during vacuum automation cycle time.

Result:

- Less compressed air usage

- Less electrical consumption

- Reduced carbon footprint

Automotive OEM’s production process — Press Shop, BIW (Body in White), paint shop and assembly lines — major vacuum automation compressed air usage is at press shop, BIW line and assembly line. Schmalz ensures to provide right products to all the vacuum automation applications, such as our 100% compressed saving ejectors – 100% pneumatically and electrically.

Real-World Transformation

Consider an automotive BIW (Body in White) line that replaced its non-air saving basic ejectors with air saving ejectors. The results were dramatic:

- Energy costs dropped from Rs. 35,000 to Rs. 13,300 per month – a 62% reduction.

- ROI was achieved in just seven months.

Across India, suppliers are discovering that air-saving ejectors don’t just cut costs – they boost reliability and sustainability. Once reserved for high-volume OEMs, these systems are now accessible to mid-tier suppliers, changing the economics of small-batch manufacturing. As I often say: “Air-saving ejectors don’t just save air — they change the economics of manufacturing.

India’s Paris Agreement commitments and OEM carbon neutrality targets make sustainability a competitive advantage. A 10-line facility can cut 43 tons of CO₂ annually — 215 tons over five years — numbers that resonate with regulators and customers alike.

Why Act Now

- OEMs demand aggressive cost reductions by 2026

- Compressed air costs keep rising

- Government PLI incentives reward efficiency

Indian manufacturing stands at a crossroads. Legacy systems drain resources, while air-saving ejectors offer a proven path to lower costs, higher reliability, and real sustainability. At Schmalz India, we invite manufacturers to schedule a free energy audit and transform their lines into models of efficiency and resilience.

Schmalz India Private Limited

Email : marketing@schmalz.co.in

Web : www.schmalz.com