KEBA has been automating machine tools for more than 40 years and is one of the few companies in the world to own their own CNC and robotics kernel. We are happy to share our experience and technologies with you in order to work together on developing solutions that enable you to rise above the competition.

Our CNC kernel has been the recognized industry benchmark for decades whenever customers are looking for high processing speeds, precision, and flexibility.

Our high-level Flexprog language and the direct expansions of the CNC kernel allow us to implement even highly specific requirements with power and efficiency.

The machining process is of crucial importance for the quality of a machine tool and its final product. For this reason, we develop and build precision tool spindles with conventional and magnetic bearings (6D spindles) as well as high-performance controllers for laser sources and galvanometric scanner axes.

Market leadership through technology partnership

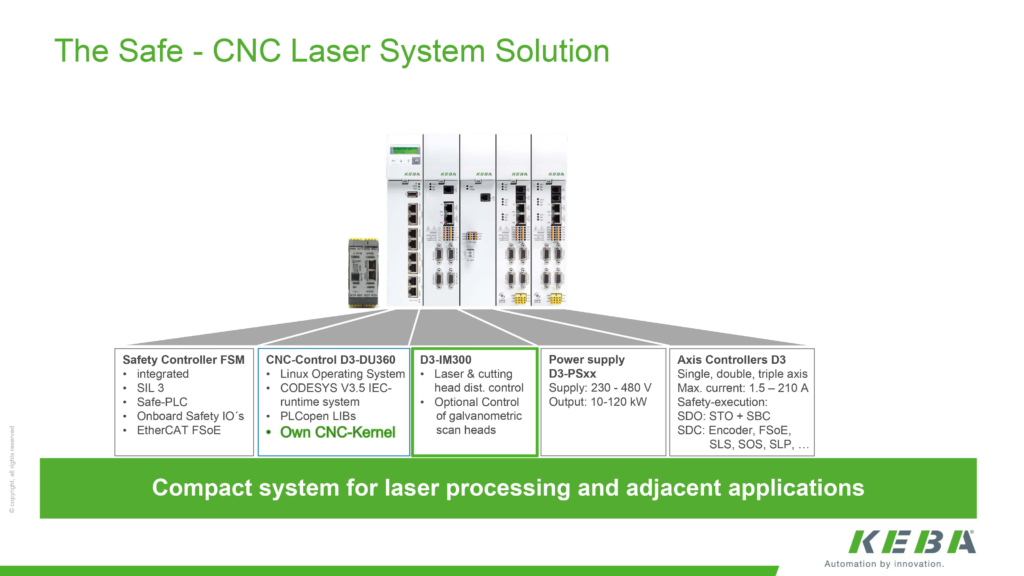

Safe, compact and energy-efficient automation systems with our proprietary CNC kernel offer maximum performance for your laser processing machine. Excellent precision even at high speeds ensured by path-synchronous laser control.

An equal partnership

Take advantage of our know-how in CNC laser processing and cutting-edge technology in automation and drive engineering, and turn it into the foundation of your success. The results of many years of partnerships and research activities have been integrated into a single comprehensive system: CNC, motion and robotics combine perfectly to achieve outstanding machine safety, intuitive operation and precise drive technology. The range of applications spans from materials processing to handling or further line integration.

Your benefits at a glance

- Compact and energy-efficient multi-axis automation system from a single source

- Flexible and high-performance due to own CNC kernel with comprehensive laser processing functionality

- Fast and precise with integrated laser control independent of path velocity

- Open, standardized interfaces to the laser periphery and the digital factory

- Safe machine solutions including consultation

- Leadership through technology partnership with a single point of contact

Tailor-made system solutions

You are the expert in laser processing. We are your partner, from the design of the machine automation system all the way to providing service for it.

We would be happy to demonstrate to you our competence for creating solutions for highly diverse applications in laser processing:

This application example shows a complete 3-axis interpolating automation system for a laser cutting machine. The CNC, the machine safety equipment as well as the intuitive commissioning and operation harmonize perfectly.

Intelligent software adds value for you

Perfectly matching software modules are the foundation for top productivity and quality. Our CNC software architecture and our proprietary CNC kernel offer you maximum flexibility. Openness and standardized interfaces guarantee a smooth integration into digital automation.

Standardized G-code in combination with our flexible FlexProg© high-level language programming allow a perfect adaptation to your machine process. The CNC technology packages offer a comprehensive range of functionality and performance.

Your benefits at a glance

- Multi-channel CNC with extremely short block cycle time (max. 100 µs)

- Extensive CNC functions for precise and optimal contours

- Flexible user programming in the CNC and the PLC

- Sophisticated technology packages for different industries

- Flexible and adaptable data interface with all CNC and technology parameters

KEBA India Private Limited

Web : www.keba.com