HVOF Gun for Tungsten Carbide Coating

In this blog post, we delve into the world of HVOF Gun for Tungsten Carbide Coating, exploring its latest price, coating materials, thickness, temperature, and versatile applications. The HVOF Gun stands as an advanced thermal spray system, expertly employed to apply durable coatings on various surfaces, significantly enhancing the performance and longevity of alloy components.

The High-Velocity Oxygen Fuel Gun for Tungsten Carbide Coating is a remarkable solution that significantly improves the longevity and performance of metal surfaces. Leveraging cutting-edge technology, High-Velocity Oxy Fuel (HVOF) guns showcase their prowess in transforming the characteristics of the coated materials.

H2 What is HVOF Coating?

HVOF coating meaning – Understanding the essence of HVOF coating, also known as “High Velocity Oxygen Fuel” or “High-Velocity Oxy Fuel” coating, it emerges as a remarkable technique for achieving high-quality coatings on metal surfaces, elevating their overall quality and resilience.

H2 HVOF Gun for Tungsten Carbide Coating India

In India, where thermal spray coating finds extensive use across diverse applications, the HVOF tungsten carbide coating takes center stage as an advanced system grounded in sophisticated technology.

The HVOF coating process involves skillfully generating a well-balanced mixture of LPG fuel, oxygen, air, and coating powder, which is then artfully applied to the metal surface using a flame gun, yielding excellent results.

Embracing the use of HVOF tungsten carbide stands as a logical choice, given its impressive efficiency and cost-effective-ness. This particular coating type is widely recognized as “HVOF carbide coating,” coveted for its superior performance.

Employing the HVOF Gun for Tungsten Carbide Coating not only ensures the highest level of coating quality but also offers substantial cost savings. A myriad of modern industries, including aerospace, automotive, steel, oil, and gas, benefit from Tungsten Carbide Coating, effectively extending the lifespan of critical components while significantly reducing maintenance costs in the long run.

H3 HVOF Coating Materials

In the realm of alloy coating facilitated by advanced guns, numerous kinds of plating or dusting powders can be employed. These include chromium carbide, aluminum oxide (alumina), cobalt-chromium, nickel-chromium, zirconium oxide (zirconia), boron carbide, titanium dioxide, and various polymer powders.

For further information on the specific materials utilized in the coating process, kindly refer to the table provided below.

H3 Understanding HVOF Tungsten Carbide Coating Thickness

In the context of HVOF guns utilized for tungsten carbide coating, the coating thickness typically ranges from 150 μm (microns) to 300 μm (microns), equivalent to 6 mils to 12 mils. The actual thickness is determined based on specific requirements, such as hardness, design, mechanical needs, and thermal conductivity of the metals being plated.

H4 HVOF Coating Thickness

According to standards, HVOF Tungsten Carbide Coating exhibits a thickness ranging 1 mils to 20 mils, however translates to approximately 25 microns to 500 microns. This thickness may vary depending on the material’s specific demand of the application where plating is used with the HVOFspraying gun.

H3 HVOF Coating Temperature

During the process of coating a metal surface using an HVOF gun, the temperature typically ranges from 2800°C to 3500°C, equivalent to approximately 5000°F to 6332°F when converted from Celsius to Fahrenheit.

Several factors come into play in influencing the temperature of High Velocity Oxy Fuel coating, including:

- Oxygen flow rate

- Fuel gas used to like – LPG

- Air Pressure

- Coating powder selection

By adjusting these factors, the plating operation should be optimized to achieve the desired results for different applications.

H2 HVOF Coating Process Explained Step-by-Step

Given below is step-by-step tungsten carbide coating operation with the help of HVOF spray gun :

Surface Preparation for Coating with High-Velocity Oxygen Fuel (HVOF) gun

To initiate HVOF operation procedure, the first step involves preparing surface. This includes removal of rust from the metal surface through grit blasting or shot blasting techniques.

Material Selection for Coating

In this step, appropriate coating stuff is established on the specific requirements of the surface. Material selection may pivot on the type of metals, alloys, carbides, or other materials to be coated.

Powder Feeding with LPG, Air Compressor, Oxygen & Nitrogen Gas Connection

Next, the chosen coating powder, such as Tungsten Carbide or Chromium Carbide, is filled into the powder feeding container.

In the third step choose the powder that you fill in the powder feeding container, for Example – we select Tungsten Carbide or Chromium Carbide and fill in the combustion chamber for coating.

After filling the powder in the chamber box, connect the LPG pipe to the cylinder on one side and to the HVOF coating chamber on the other side. After that connect the air compressor pipe from one side to the cylinder and the other side to the HVOF chamber.

Then after it is connected, connect the Oxygen gas pipe from one side to the cylinder and from the other side to the HVOF chamber. Finally, connect the Nitrogen gas pipe on one side to the cylinder and the other side to the HVOF chamber.

After connecting each other, start connecting the second output from the chamber to the HVOF spray gun. In the HVOF Gun for Tungsten Carbide Coating (High-Velocity Oxy Fuel gun), four types of pipe connected to the gun from the chamber or HVOF control panel.

Start Coating on the Application

Once all the necessary connections and settings are in place, the HVOF spray coating process is initiated. The correct velocity and temperature settings are adjusted to ensure proper melting of the powder and a strong mechanical bond with the adherent coating.

Cooling and Inspection or Quality Control

In the last step, coating is applied to the metal surface, it is cooled using an air compressor or inert gas. From hot to cool the process solidifies plating on the surface. Quality inspections are conduc-ted to check if the alloy adheres properly & meets the necessary specifications in terms of wideness & hardness. If needed, alloy sides may undergo re-coating.

The HVOF spraying gun coating process is a reliable method widely used in diverse industries, including space engineering, oil and gas, manufacturing, defense & military, marine, and medical fields.

H3 Main Components of the HVOF Tungsten Carbide Coating Machine :

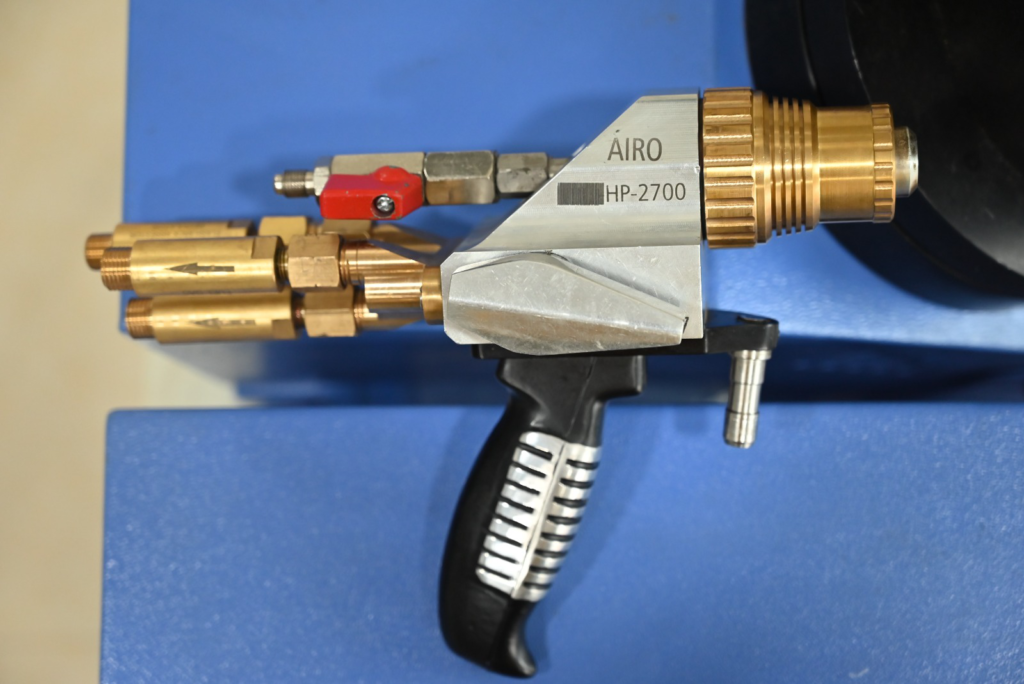

HVOF Spray Gun :

An advanced gun used for coating metal surfaces.

Powder Feeder Pipe :

Connects the HVOF gun and HVOF panel directly for powder feeding.

Air Pipe :

Connects the HVOF spray gun and HVOF panel for supplying air.

LPG Pipe :

Connects the HVOF gun and High-Velocity Oxy Fuel panel for supplying LPG fuel.

HVOF Gun Controller Panel :

Serves as the central hub connecting the LPG gas cylinder, oxygen cylinder, aircompressor, nitrogen cylinder, HVOF spray gun, and powder feeder.

NRV (Non-Return Valve) :

Prevents backflow of gases or powders in the system.

Pressure Meter :

Indicates air pressure in the meter.

Air Inlet and Outlet Pipe :

Air pipe connects the HVOF control panel to the air compressor tank and the HVOF spray gun.

LPG Inlet and LPG Outlet Pipe :

LPG pipe connects the HVOF control panel to the LPG cylinder tank and the HVOF spray gun.

Oxygen Inlet and Oxygen Outlet Pipe :

Oxygen pipe connects the HVOF control panel to the oxygen cylinder tank and the High-Velocity Oxy Fuel spray gun.

Nitrogen Inlet and Outlet Pipe :

Nitrogen pipe connects the HVOF control panel to the nitrogen cylinder tank and the HVOF spray gun.

In the HVOF spray gun, four pipes are connected, namely LPG gas, Air, Oxygen, and Powder feeder pipes.

H3 HVOF Powder Feeder Instructions

The HVOF Powder Feeder is equipped with the following components and controls:

- Motor RPM Controller Button (On/Off)

- Nitrogen Controller (On/Off)

- Motor Speed Slow/Fast Controller

- Power Supply Indicator (On/Off)

- Oxygen/Nitrogen Flow Meter with LED Indicator

- Powder Feeder NRV(Non-Return Valve)

- Pressure Meter (2 Kg), NRV Up/Down after Nitrogen Controller (On/Off)

- Four Clamps for Powder Feeder Box (Open/Close)

- Powder Tank Capacity 10 Kg (3350 Powder Feeder Model)

H3 Check Parameters before Starting HVOF Spraying Gun

Before starting the HVOF Spraying Gun, ensure the following parameters are checked :-

- Air Meter Shows (400-500)

- LPG Fuel Meter Shows (40-50)

- Oxygen Meter Shows (225-250)

- Air Pressure Gauge Shows – 7 bar

- LPG Pressure Gauge Shows – 6 bar

- Oxygen Pressure Gauge Shows – 10 bar

- Main Heater Air Button On/Off

- Red Indicator – Low Pressure

- Green Indicator – Ready to Use

H2 HVOF Coating Applications

High-Velocity Oxygen Fuel (HVOF) coating finds numerous applications across various industries:

H3 Aerospace:

HVOF coating machines are extensively used in the aerospace industry for parts such as turbines, engines, and aircraft components. The coating enhances surface erosion resistance and durability.

H3 Industrial Equipment:

In manufacturing industries, HVOF coating is applied to metal tools, hydraulic cylinders, molds, and cutting tools to increase hardness, wear resistance, and overall lifespan.

H3 Automotive:

The automotive industry utilizes HVOF coating to improve the performance and durability of engine components, pistons, rings, and brake parts.

H3 Oil and Gas:

In the oil and gas sector, HVOF gun for Tungsten Carbide coating is employed to protect drilling equipment, pumps, and valves from abrasive wear, corrosion, and

chemical attacks.

H3 Defense and Military:

HVOF powder coating is utilized to enhance the lifespan of defense and military applications, including gun barrels, grinding balls, wear plates, armor plates, and more.

H3 Electronics:

In the electronics industry, HVOF coatings serve to insulate wires, coat the surfaces of electronic components, and create thermal barriers.

H3 Medical:

HVOF coatings are applied in the medical industry for medical equipment such as surgical instruments, dental instruments, implants, microsurgical tools, surgical staples, clips, and medical devices.

H2 HVOF Gun for Tungsten Carbide Coating Price in India

In India, the price of an HVOF Tungsten Carbide Coating Gun can vary depending on several factors, including the manufacturer, brand name, model number, technology used, and specific features.

The price range for an HVOF gun for tungsten carbide coating falls between Rs. 50,000 to Rs. 200,000. Various factors, such as air-cooled or liquid-cooled, small or large guns, and the inclusion of multiple spray nozzles, can influence the price of the High-Velocity Oxygen Fuel gun.

Shot Blaster

Web : www.thermalspraygun.com