Sustained success with material handling in plate cutting industry.

Messer Cutting Systems India Pvt Ltd

Main concern in a fabrication industry is on storing and handling material. The traditional storage and handling practices can negatively impact the fabrication industry by causing operation in efficiencies, safety hazards, product quality issues, space utilization problems and increased costs.

The utilization of manual material handling is frequently hindered by human limitations, resulting in slower process, elevated risks and ultimately reduced Improper handling can result in loss of traceability of materials causing project delays, surface damages like scratches, dents or warping.

Material handling challenges within a manufacturing sector can have substantial impact on efficiency and productivity.

Solution:

Proper material storage and handling in sheet metal and plate cutting industry reduces the challenges by

- Materials are moved, stored and controlled effectively. This reduces downtime and enhances productivity.

- Significant reduction in workplace accidents and maintain a safe working environment.

- Proper handling helps maintain the integrity and quality of the products.

- Optimize use of available space

- Easier access to materials, reducing clutter and improving workflow.

- Reduce cost associated to material damage and rework.

- Minimize workplace accidents.

- Help maintain a balance in inventory which is crucial for streamlined production.

A well-thought-out plan for layout aims to minimize these dead spaces, optimizing the storage area and enhancing overall efficiency.

While initial costs are associated with material handling equipment, it is a critical investment for efficient material handling. Smart investment in the latest material handling machines not only saves money in the long run but also improves efficiency. Machinery operates at a faster pace than manual labour, and newer equipment tends to be more energy-efficient, thereby reducing expensive fuel costs.

Maintaining a uniform processing speed throughout all systems and processes is essential for the efficient and stress-free handling of goods and materials.

Maximizing vertical space with racks and shelving systems provides optimal storage solutions, overcoming space constraints.

Real-Time Tracking provides real-time visibility into inventory levels, ensuring accuracy and timeliness. Efficient tracking helps prevent stockouts and overstocking, optimizing inventory levels for smooth production.

Navigating the common challenges in the material handling industry requires a strategic and proactive approach.

As a company committed to providing solutions, We at Messer cutting systems understand and offer comprehensive solutions to cater to most fo the plate and sheetmetal cutting industry.

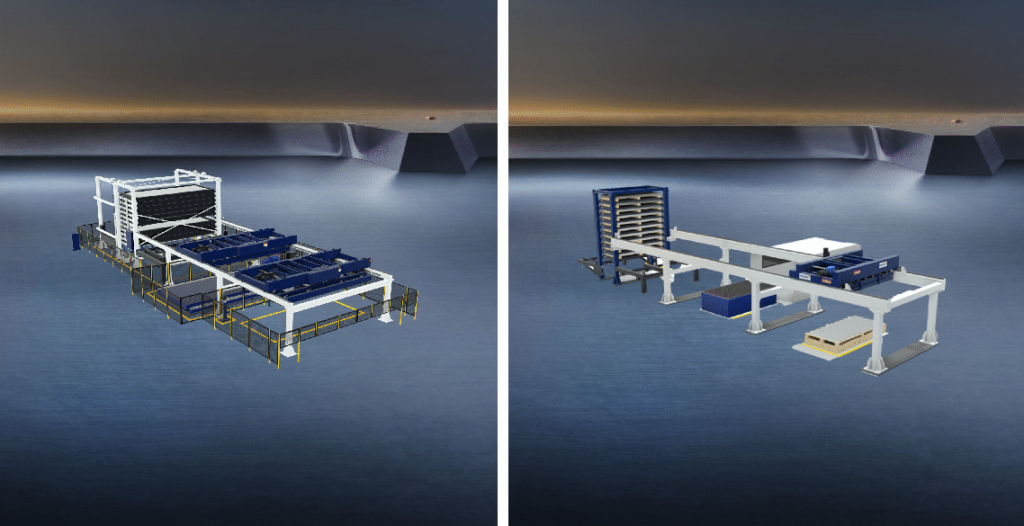

Messer offerings include

- Vertical storage

- Material movement by use of vacuum loader and unloaders

- Cut parts picking

- Customized material feeding systems.

Our storage systems can be coupled with the handling systems to store and feed plates to the cutting machines without using manual labor.

Messer offers systems for large plate handling upto 7.5mt length which can be coupled with multiple machines which can be configured limitlessly to adapt customer functions.

Also available are compact systems useful for single machine application for fast and easy material loading and unloading.

In addition we also offer cut parts picking and sorting systems.

In total we help in optimizing cutting solutions, implementing automation, enhancing safety protocols and digitizing process for increased productivity and streamline production.

Partner with us to transform your challenges to opportunities with efficient material storage and handling process.

Messer Cutting Systems India Pvt Ltd

Web : www.in.messer-cutting.com