Precihole Machine Tools Pvt. Ltd.

Precihole Machine Tools has stood as a symbol of excellence in precision engineering. From mastering deep hole drilling to delivering complete solutions across defense, aerospace, automotive, energy, and medical sectors, the company has consistently pushed the boundaries of what manufacturing accuracy can achieve. Today, Precihole marks another milestone by introducing Abrasive Flow Finish Machining (AFFM) — a process that brings a new dimension to surface perfection and component performance.

Understanding the Process

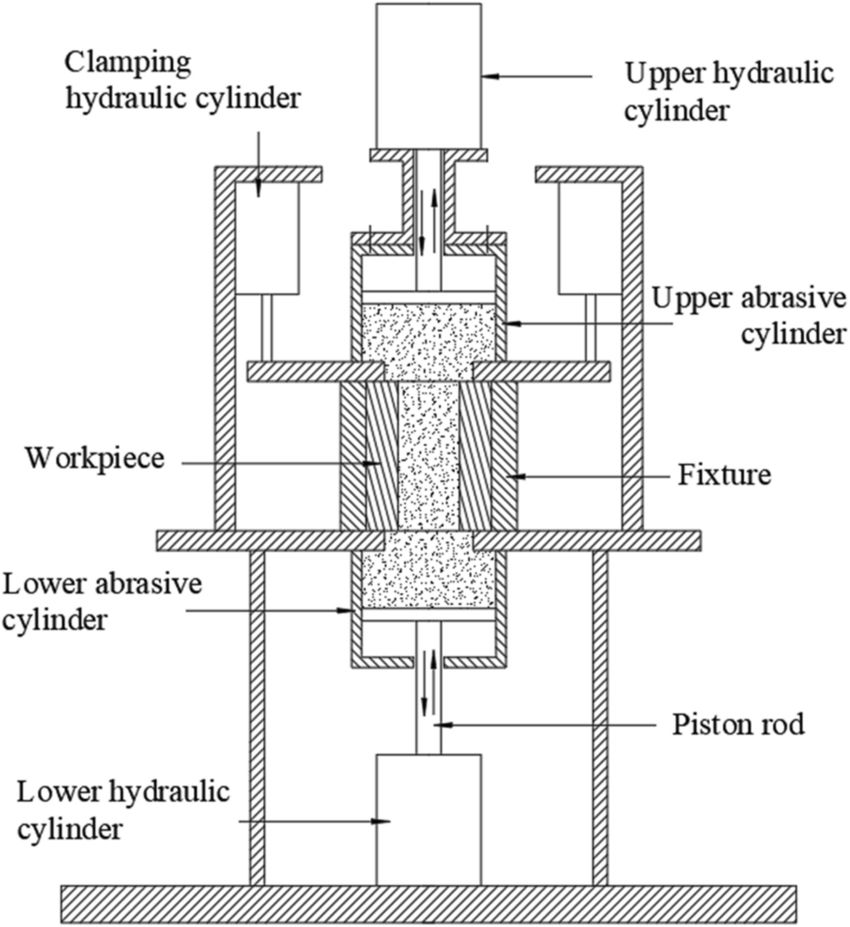

Abrasive Flow Finish Machining is a specialized surface refinement technology designed to polish, deburr, and finish internal passages that are otherwise unreachable by conventional tools. The heart of the process lies in its abrasive-laden polymeric media — a thick, putty-like substance infused with abrasive particles such as silicon carbide, aluminum oxide, or boron carbide.

This media is hydraulically extruded back and forth through the component. As it flows, each embedded abrasive particle acts like a microscopic cutting tool, gently removing high points and surface irregularities. The process doesn’t just clean the surface — it enhances it at a microscopic level, achieving finishes as fine as 0.05 µm Ra with remarkable consistency.

The key advantage lies in the shear-based material removal mechanism, which avoids the dimensional distortion often seen in other finishing methods. The result: a uniform, repeatable finish even on parts with complex geometries, intersecting holes, or deep internal channels.

Why It Matters

In modern engineering, surface integrity is performance. Whether it’s ensuring a laminar flow in a fuel injector, extending the fatigue life of a turbine blade, or ensuring the reliability of a firearm barrel – every micron of surface finish counts. Poor surface quality can lead to turbulence, early fatigue, stress risers, or inefficient flow characteristics.

AFFM addresses these issues at their root. By creating an ultra-smooth, controlled internal surface, it enhances component behavior in service – improving flow efficiency, wear resistance, and fatigue strength – while simultaneously ensuring dimensional accuracy.

Applications Across Key Sectors

- Aerospace: For turbine blades, fuel nozzles, and hydraulic manifolds, AFFM delivers smoother internal flow paths and increased fatigue resistance, vital for flight safety and efficiency.

- Automotive: Used to finish intake and exhaust manifolds, injectors, and combustion parts, leading to better airflow, reduced friction losses, and improved engine efficiency.

- Medical: Provides flawless, biocompatible finishes on implants and surgical tools where both smoothness and precision are critical.

- Energy: Enhances performance of valve bodies, pump components, and high-pressure fittings that demand absolute sealing integrity.

- Defense: Removes burrs and improves surface finish in barrels, slides, and receivers — elevating both accuracy and service life of precision weapon systems.

Each of these sectors benefits not only from the technical precision but also from the repeatability and automation potential of AFFM. The process is easily programmable, making it ideal for both prototype development and series production environments.

Performance Characteristics

- Surface Roughness: Achievable finishes down to 0.05 µm Ra.

- Dimensional Stability: Minimal deviation even after multiple cycles.

- Material Removal Rate: Low and controlled for precision-critical applications.

- Cycle Efficiency: Optimized balance of time, cost, and finish quality.

The Precihole Advantage

Precihole’s entry into AFFM is not a random diversification-it’s an evolution born from experience. Having mastered deep-hole drilling for decades, the company naturally extends that expertise to the next logical frontier: finishing those holes to perfection.

With strong R&D capabilities, in-house manufacturing, and a deep understan-ding of material behavior, Precihole offers AFFM systems that are not only reliable but also custom-engineered for customer needs. The technology can be scaled for a single R&D setup or integrated into a high-volume automated production line.

This synergy between process knowledge and practical application ensures that every AFFM solution from Precihole is consistent, scalable, and globally benchmarked.

Redefining Surface Perfection

At its core, Abrasive Flow Finish Machining is not just about achieving a mirror-like finish — it’s about enhancing how components perform over their entire lifespan. A smoother surface means less friction, more predictable behavior under load, and longer-lasting reliability.

By championing this technology, Precihole reinforces its position as not just a machine builder, but a partner in precision manufacturing — one that helps industries move closer to the ideal of zero-defect performance.

In Summary

Abrasive Flow Finish Machining is where art meets science in modern manufac-turing. It embodies the philosophy that every surface tells a story — of efficiency, durability, and excellence.

Precihole Machine Tools Pvt. Ltd.

Web : www.precihole.com