How Mastercam Optirough can save you hours of CNC Programming Time

What is Mastercam OptiRough?

The Dynamic OptiRough in Mastercam is the same widely used and trusted technology that users have been employing for over a decade. The only difference is that now OptiRough has been added to all levels of Mill and Router, making it available to all customers.

Experienced OptiRough veterans will be thrilled with the new ways to use its reduced cycle times and increased tool life in Mill. New users will be relieved by how easy it is to use this all-encompassing roughing strategy. With just a few clicks, a programmer can create powerful, safe, and efficient programs for their entire part.

How Mastercam OptiRough Works

Dynamic Motion applies optimized cutting motion to any set of geometry. When feeds, speeds, and angles are not optimized, unnecessary heat builds up, overheating the tool and its protective coating. Too much heat and the tool is damaged or destroyed completely. When a tool becomes damaged, it loses its shearing ability and begins to tear material instead of cutting it cleanly. The result is damaged tools, ruined stock material, and wasted time. Dynamic avoids this by consistently monitoring the tool and stock and by dynamically adjusting the motion of the toolpath such that the tool remains safe. But how does it accomplish this? By exploiting the power of radial chip thinning.

Radial chip thinning (RCT) occurs any time the stepover amount or the width-of-cut is less than the radius of the tool. As less of the tool is engaged with the material, thinner cuts are taken from the stock. If the chips become too thin, they stray outside the tool manufacturer’s recommendations, the machine becomes underfed, and efficiency drops. To bring the chip thickness back up to desired parameters, feed rates need to be increased. For example, if only 25 percent of the tool’s diameter is engaged and a chip thickness of .005” must be met, the programmer (or software) must multiply .005” by a feed rate multiplier of 1.15 to find the adjusted feed per tooth.

The benefit of employing this concept is not only increased feed rates. Because of the smaller stepover, the stepdown can now go much deeper (typically twice the tool diameter). The chip thickness is maintained over the entire flute length while still staying within the parameters of the tool’s design and shearing capability. Additionally, there is less tool notching and a reduced side load with a deeper stepdown, which in turn extends tool life.

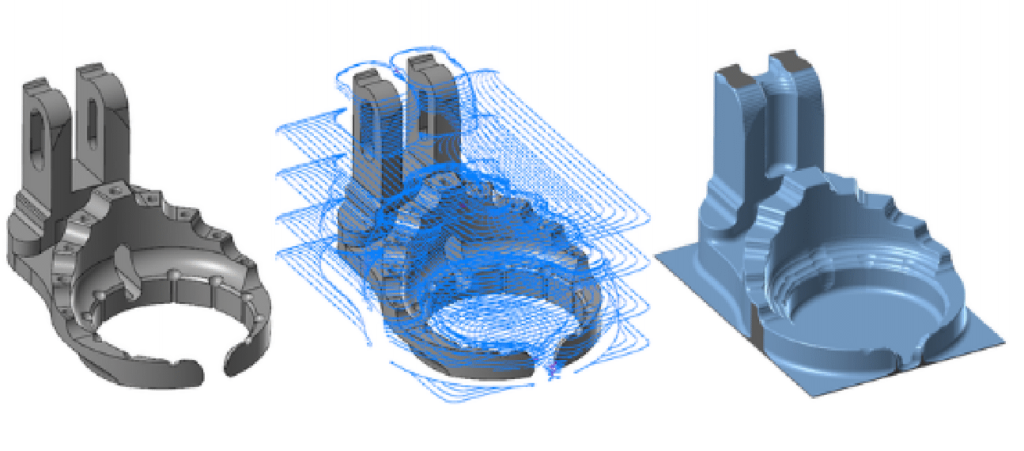

Dynamic Motion technology, which powers OptiRough, harnesses the theory of RCT and applies it not only to straight line passes, but to any set of geometry a programmer can come up with. The “dynamic” part of the technology lies in how the proprietary algorithms that run it dynamically adjust the tool motion and feed rates to keep cutting conditions optimized. The benefits are three-fold-increased tool life, greater machining efficiency, and maximum material removal.

Save Time with Mastercam OptiRough

Dynamic OptiRough saves programmers time in three major ways—the simplified, consistent toolpath replaces multiple less advanced toolpaths and cuts programming time; the optimized cutting conditions reduce the chance of tool breakage and the need to stop machining for extra set-ups, and the cycle time is drastically reduced.

Consider the Chain Guard Signature Part. The original part was programmed with 16 2D operations to cut the first setup. Now that OptiRough is included in Mill, the programming was reevaluated. Mastercam Application Engineers found that one OptiRough strategy was able to replace all 16 traditional operations, with the same net results at the machine. Putting that in terms of a skilled programmer’s time means significant cost savings.

Founded in 2016, Mastercam India Pvt. Ltd. is headquartered in Pune, Maharashtra. The company brings Mastercam, a suite of CAD/CAM software created to reduce production time and expense with efficient machining strategies and advanced toolpath technologies like Accelerated Finishing™ and Dynamic Motion™. Mastercam is the world’s #1 CAM software, with more than 3,00,000 installations in industries such as aerospace, automotive, medical, tool making, energy-oil and gas, education, and prototyping.

Web : www.mastercamindia.com